Capabilities: Production, Assemblies, Material chain, Engineering, Quality Assurance& Control

Production Technology

Production is operating in two sites: Snir & Topaz located in Kiryat Gat industrial zone in Israel. The overall production capability of the company is highly extended and its plants are spread on an area of approx. 21,000 m2.

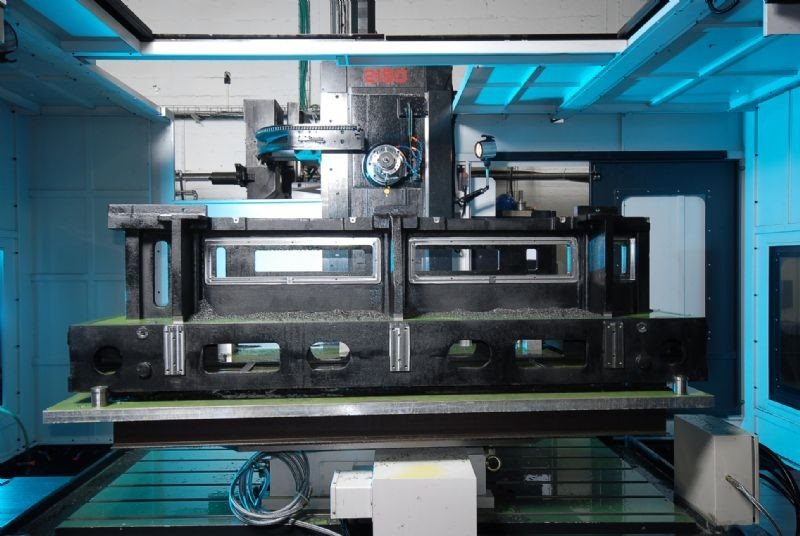

The production activates approx. 90 CNC processing centers, of which:

About 55 processing centers in milling, including 5-axes machines and work tables X-2500, Y-1700 cm in dimension, type: Hitachi, Mazak, etc.

Additionally, about 9 processing centers in turning/machining, up to 350 mm in diameter with milling capability; the types of the machine are Mazak, Star.

The production floor has full air-conditioning control to ensure conformance to the spec. requirements.

Additional Capabilities

Complete SPC self-control, including data collection, analysis and improvement of processes:

Implementation of skim production / KANBAN in major business processes

Configuration management using PDM methods

Improvement and optimization activities

Material Chain

The company has shown proven capabilities in managing suppliers and procurement in Israel and abroad, including "low cost" countries pertaining to technologies, such as: coatings, heat treatment, grinding, metal sheet, welding, and so forth.

Configuration control is carried out using PDM techniques.

Additional areas of activity are presented in the following scheme:

Engineering

Engineering is responsible for four areas of activity:

* Development – The Engineering Dept. is capable of developing products based on customer specifications. The vast experience existing in the integration of DFM methodologies in product development is the prominent part of the company"s activities. The team provides DFM workshops for customers, including support to the customer"s R&D teams.

* Engineering – This area of activity involves the introduction of new products, production and assembly processes development as well as engineering modifications in the product.

* Technologies – Developing new technologies in the machining and assemblies areas. An additional area is the development of fixtures, testing apparatus and fixture means. The fixture means “Easy-Fix” is a flag product for measuring machines.

* Quality Engineering – Planning quality into the processes, setting quality control methods.

Quality Assurance & Control

The quality system implemented at Hameshavev Company conforms and certified to the requirements of ISO 9001:2015 standard and AS9100:D Aerospace Industry. The system is designed and implemented in such a manner to comply with the various requirements and standards of the different customers and will be qualified by these customers. In addition, the quality system ensures the implementation of the requirements of rules and regulations, quality of the environment aspects and prevention of environmental pollution.

The production and assembly processes are statistically controlled (SPC) and total quality controlled (TQC); both are managed by an array of skilled inspectors.

The measuring array includes: 18 CMM (DEA) measuring centers under precision of +/-2mic, a measuring table up to X-5100,

Y-3000, Z-2500 in dimensions, a video measuring head, "Marposs" measuring heads for precise traits up to 0.5m, TRIMOS electronic altimeter, comparator, conventional measuring tools (dozens of calibers and micrometers of all types and sizes, complete sets of Johanson blocks, pins, gauges, screw gauges).

These instruments are calibrated by certified laboratory; the quality system is regularly tested by an external certificafied body.